Exactly How to Prevent Weld Undercut: Necessary Tips for Welders

Exactly How to Prevent Weld Undercut: Necessary Tips for Welders

Blog Article

Mastering the Art of Welding: Exactly How to Stay Clear Of Undercut Welding Issues for Flawless Manufacture Results

By understanding the origin triggers of undercut welding and applying efficient methods to prevent it, welders can elevate their craft to new degrees of excellence. In the quest of perfect manufacture results, mastering the art of welding to prevent undercut problems is not just an ability however a necessity for those striving for excellence in their job.

Recognizing Undercut Welding

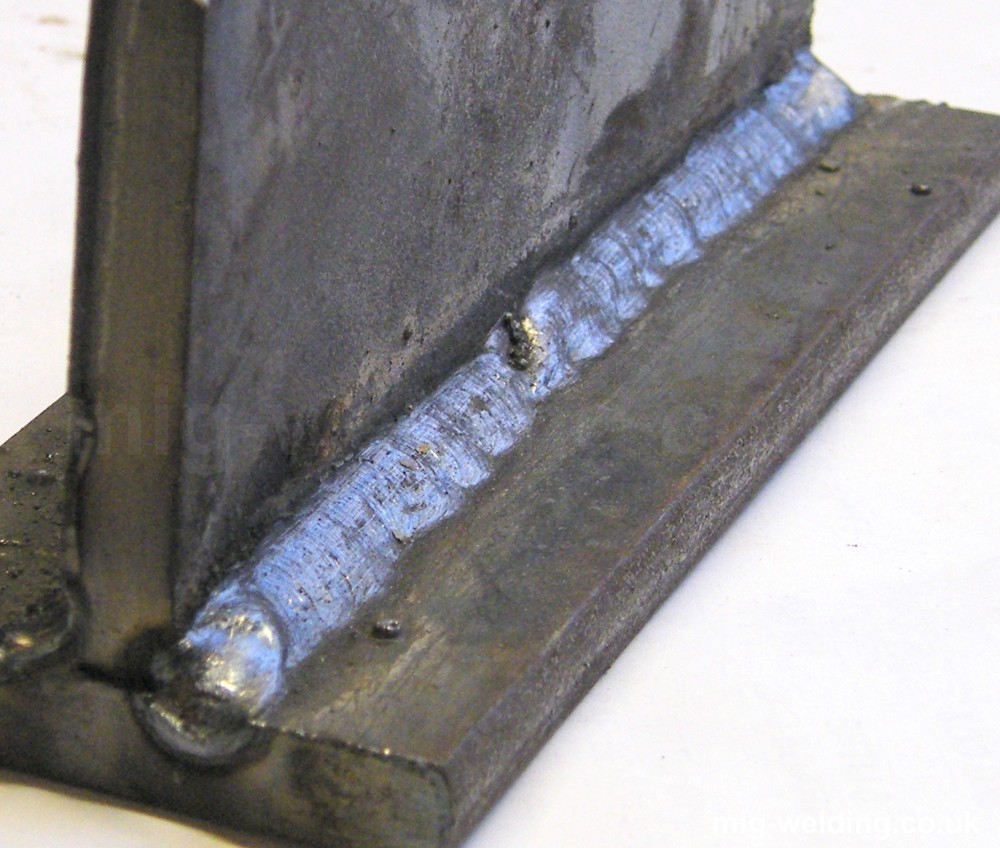

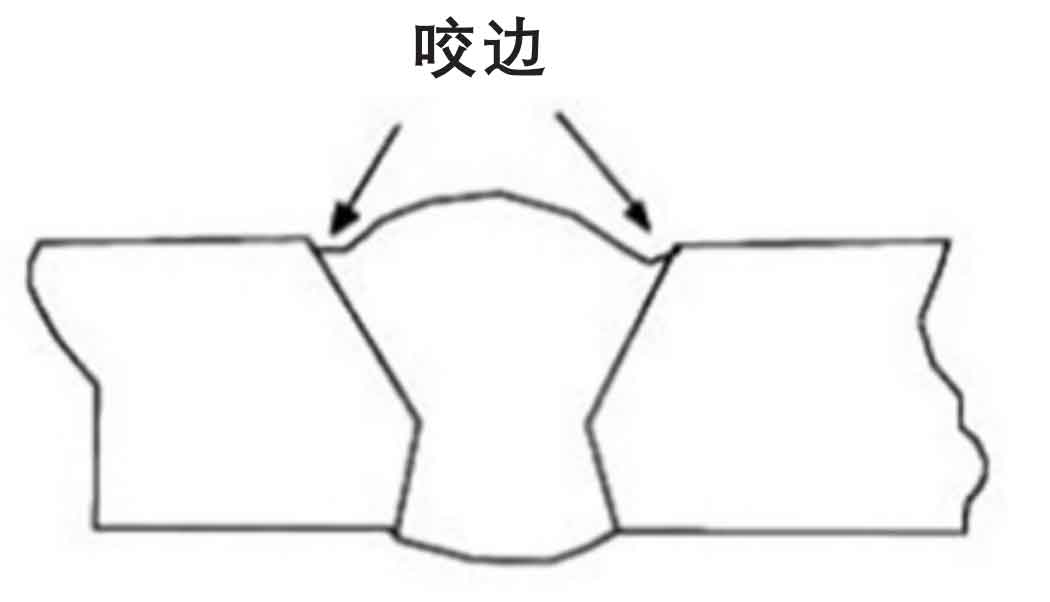

To stop undercut welding, welders need to ensure correct welding specifications, such as changing the current, voltage, traveling rate, and keeping the proper electrode angle. Furthermore, making use of the suitable welding method for the certain joint setup is important. Using weaving motions or backstepping techniques can assist ensure proper weld metal deposition and minimize the likelihood of undercut development. Regular assessment of welds throughout and after the welding process is also important to capture any type of undercut very early and make needed modifications to stop additional problems. Preventing weld undercut. By understanding the reasons for undercut welding and applying preventative actions, welders can attain top quality, structurally sound welds.

Reasons For Undercut in Welding

Understanding the elements that add to undercut in welding is essential for welders to generate top notch, structurally audio welds. Inadequate welding inaccurate or existing welding speed can likewise add to damage. Recognizing these causes and applying correct welding methods can aid stop damaging concerns, making certain strong and sturdy welds.

Techniques to stop Undercutting

To alleviate the threat of damaging in welding, welders can employ strategic welding strategies intended at enhancing the top quality and honesty of the weld joints. Furthermore, making use of the appropriate welding strategy for the certain joint arrangement, such as weave or stringer grains, can add to reducing damaging.

Moreover, correct joint preparation, consisting of ensuring clean base materials without impurities and using the proper welding consumables, is critical in protecting against undercut flaws. Using back-step welding strategies and managing the weld bead profile can additionally aid distribute warm equally and lessen the risk of undercut. Routine inspection of the weld joint during and after welding, along with carrying out top quality assurance measures, can assist in spotting and dealing with damaging concerns quickly. By applying these techniques vigilantly, welders can achieve remarkable construction results with minimal undercut issues.

Relevance of Correct Welding Specifications

Choosing and preserving proper welding criteria is crucial for achieving successful welds with marginal flaws. Welding specifications describe variables such as voltage, present, travel speed, electrode angle, and securing gas flow rate that straight impact the welding process. These parameters have to be read this article thoroughly changed based on the kind of material being welded, its density, and the welding technique utilized.

Correct welding parameters ensure the correct amount of warm is put on thaw the base steels and filler product uniformly. If the criteria are set too expensive, it can lead to extreme heat input, triggering distortion, burn-through, or spatter. On the various other hand, if the parameters are also reduced, insufficient blend, lack of infiltration, or undercutting might happen.

Quality Control in Welding Operations

Conclusion

To conclude, understanding the art of welding calls for an extensive understanding of undercut welding, its causes, and techniques to stop it. By ensuring correct welding criteria and implementing high quality assurance methods, remarkable manufacture outcomes can be attained. It is important for welders to constantly make every effort for excellence in their welding operations to prevent undercut concerns and create high-quality welds.

Undercut welding, a typical problem in welding processes, happens when the weld metal does not effectively fill the groove and leaves a groove or clinical depression along the welded joint.To avoid undercut welding, welders ought to guarantee proper welding specifications, such as adjusting the current, voltage, traveling rate, and keeping the correct electrode angle. Poor welding incorrect or existing welding rate can also add to undercut.To mitigate the danger of undercutting in welding, welders can use critical welding strategies intended at enhancing the top quality and integrity of the weld joints.In conclusion, mastering the art of welding requires a detailed understanding of undercut welding, its causes, and strategies to prevent it.

Report this page